Palm oil mill effluent (POME) is a high viscous liquid discharge generated from crude palm oil extraction process. It is mainly produced from two major processes that use vast amount of water:oil palm fresh fruit bunch (FFB) sterilization and kernel-shell separation processes. These processes generate effluent with high pollution properties containing oil, grease and solids.

In Malaysia, a palm oil mill can approximately process as high as 20 to 50 metric tonnes of FFB per hour a day, and some may have higher processing capacity. For every metric tonne of the FFB processed, 0.7 to 1.0 m3 of raw POME are generated. In year 2020, the production of crude palm oil (CPO) in Malaysia is 19.14 million tonnes . For that reason, the production of POME was undeniably increased during the period corresponding to the increase in CPO production. The conventional treatment method that is implemented by majority of palm oil mills in Malaysia and Indonesia is the ponding system. POME is treated through anaerobic digestion without or with methane capture followed by utilization of treated POME as liquid fertilizer or further treatment (aerobic process) to fulfill the wastewater quality standard. Discharging it to the river without treatment is violation according to Malaysia Environment of Quality Act (EQA) 1974.

Though ponding system of POME treatment is considered as economical treatment method due to its low capital, maintenance and operation cost. However, some may consider this treatment method to be ineffective and obsolete as it requires vast space, need long hydraulic retention time (HRT) and emits greenhouse gas with unpleasant odour to the environment.

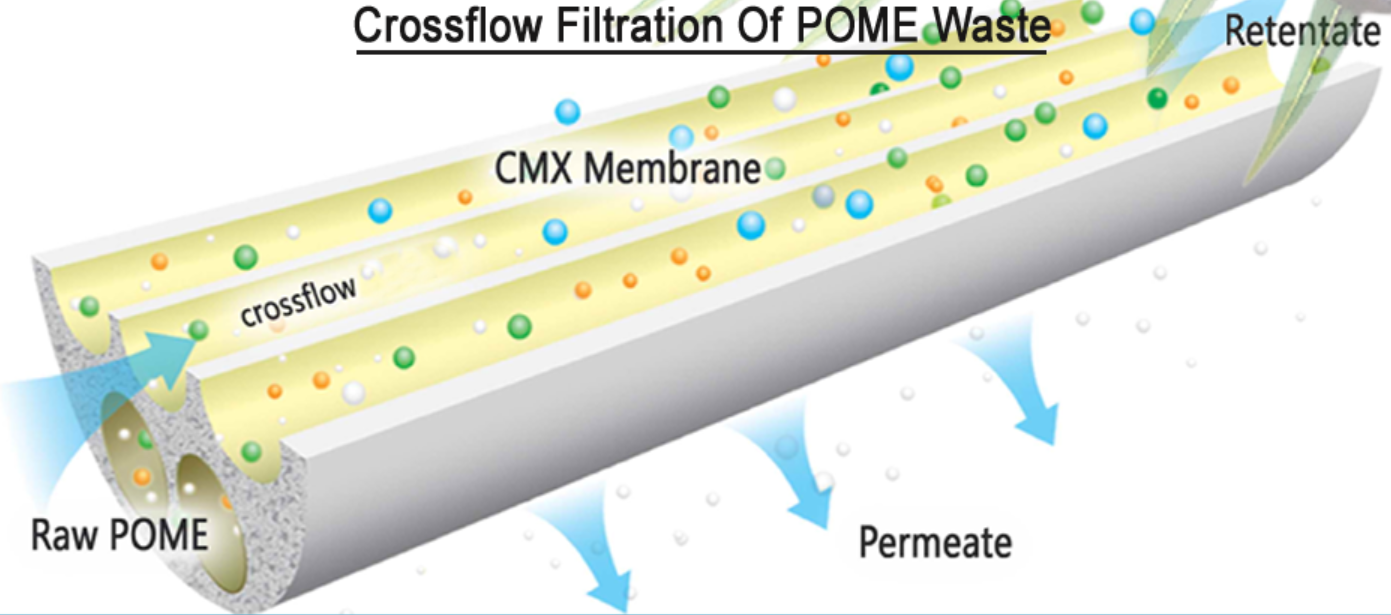

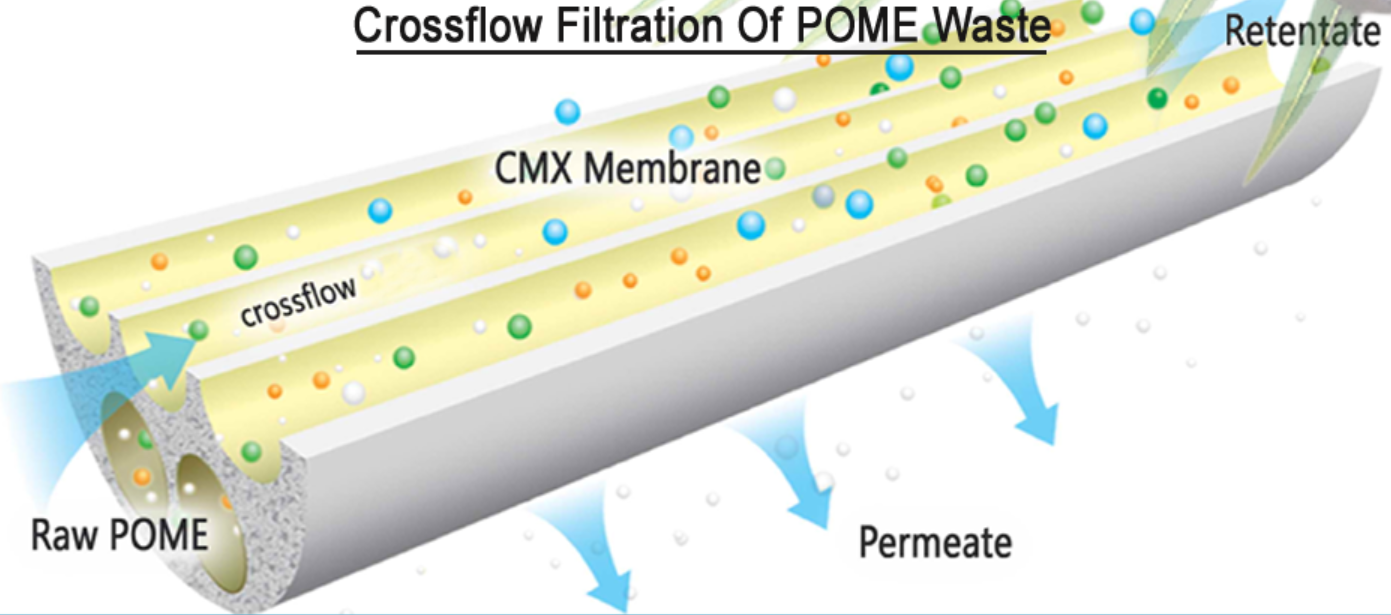

Crossflow Filtration of Ceramic Membranes

Recent years, ceramic membranes have seen widely applied for waste water treatment in chemical and food industry. Compared with biological process, crossflow ceramic membranes can bring a stable, reliable performance with high rejection of oil, SS, recycling high value palm oil. It has been proved to be a green and economical process for POME treatment.

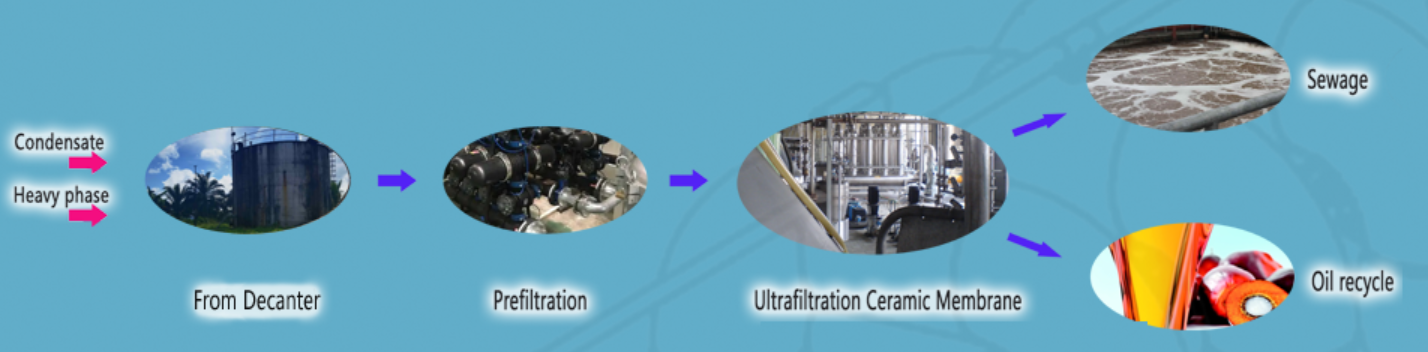

Flow Diagram of POME Treatment by CRM Membranes

Process advantages for POME treatment by UF Ceramic membranes:

- High rejection of oil, high quality of filtrate.

- Palm oil can be recycled.

- Easy post treatment.

- A green technology with less waste.

- Reliable performance on long period.

- Compact footprint.

Ceramic Membrane System for POME waste water treatment

With 28years experience on ceramic membrane technology, TFT can produce a high quality membrane product, make an integration on filtration technology , offer professional support and service. TFT commits to working hard to give POME treatment solution for palm oil plants. TFT welcome more communication and cooperation with those who are interested in this innovative technology.